Product development and co-development of silicone parts

Technical support with product design and feasibility

Your design is important to us

We provide precisely the level of support you require

No matter whether you

- approach us with a drawing of or a rough idea for your component;

- simply require support with the choice of material or only have details on the function of your component;

- have already worked with silicone or not.

We work with you to find a solution, providing technical support with product design and regarding the feasibility of your silicone and multi-component parts.

Full or co-development

If required, we can provide end-to-end assistance, starting with the initial idea, but we are also happy to work as a co-developer or development partner for individual aspects of the design. Close collaboration with our customers, suppliers and other in-house departments allows RICO’s R&D unit to fall back on a comprehensive materials and knowledge database .

Our customers benefit from our employees’ decades of experience , collected in the course of the numerous projects successfully implemented since 1994, as well as the continuous improvement of our mold concepts and production processes.

Our production development services

Wide-ranging materials expertise

- In-house materials lab

- Support with the selection of suitable materials for both 1K and 2K molding

- Mechanical characterization of materials

- Reverse engineering of unfamiliar but suitable material combinations

Optimization and analysis

- Component validation for compliance with a range of different standards and guidelines

- Analysis to determine the causes of component failure

- Optimizing part geometry in terms of function and production: evaluation of technical feasibility and efficiency in the production process; support with tolerance setting and production in accordance with blueprints

Experiments and tests

- Jointly coordinated preliminary tests, e.g. testing potential material combinations, tightness, flow rates, etc.

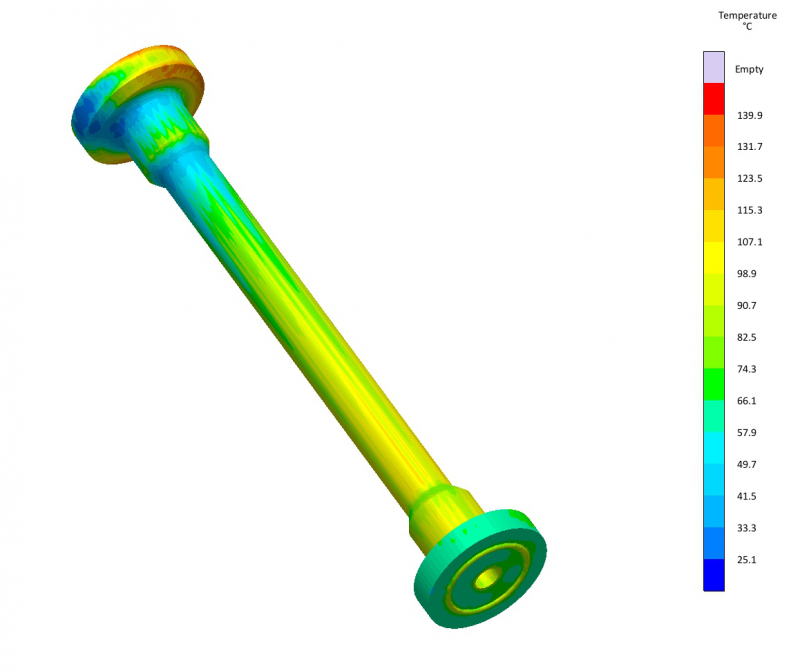

Simulations

- Filling simulations

- Thermal multi-cycle analysis

- FEM calculations

Co-development

- Component development support right through to component design

- Help with choosing suitable external testing labs

- Support with the selection of applicable ancillary processes, e.g. for surface activation

- Production of prototypes in genuine LSR materials and different colors

- Evaluation of subsequent processing steps and gaining insights into the customer’s overall concepts; integration of functions if required

If you’re interested,

contact us today.