Topline & Smartline

RICO Elastomere Projecting GmbH presents new tool product lines

Topline & Smartline

2 concepts many possibilities

RICO Elastomere Projecting GmbH, a leading supplier of high-performance tooling and elastomer solutions, is pleased to announce the launch of its two new product lines, Smartline and Topline, innovative tooling concepts that offer numerous advantages for the manufacture of elastomer products and set new standards in the industry.

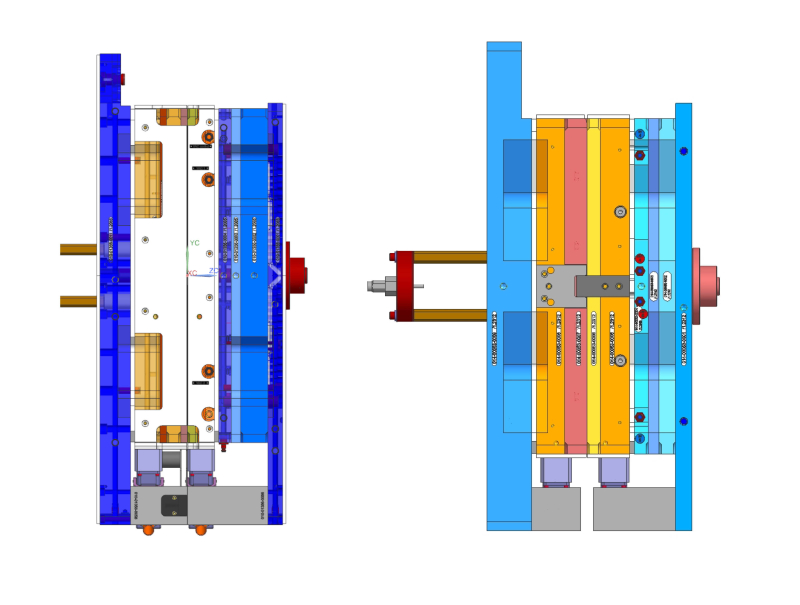

Topline tools

Topline tools are characterized by their individual adaptation to the respective product and offer the longest possible service life and best performance. These tools are specially designed to meet the most demanding requirements and offer tailor-made solutions for maximum precision and efficiency in a compact space.

Smartline tools

The Smartline mould concept is based on standardization and enables the greatest possible use of common parts as well as easy exchangeability for cavity inserts. Smartline offers a solution approach with 2-plate and center-plate molds with a total of eight molds per concept.

Important features & benefits of Smartline tools

- Fewer components for interchangeable inserts and therefore cost savings.

- Standardized manufacturing methods lead to 30% cost savings.

- Increased availability of spare parts through the use of factory standard parts.

- Optimum processes thanks to the use of the same steel qualities as in the Topline molds for cavity inserts.

- Quick quotations thanks to standard parts such as radial and axial seals directly from the price list.

- 30% shorter delivery times thanks to standardized master tools and factory standard parts.

Included in standard:

- Centering ring with a diameter of 125 mm (other dimensions optional).

- Socket for immersion nozzle with a diameter of 20 mm (other dimensions optional).

- Euromap drilling pattern with 4 x Ø 18 mm.

Optionally selectable:

- Centering ring with a diameter of 125 mm (other dimensions optional).

- Socket for immersion nozzle with a diameter of 20 mm (other dimensions optional).

- Insulating plates on the clamping plates.

- Lateral insulating plates on the heating platens.

- Heating cable.

- Vacuum hose.

- Totalizer.

- Ejector coupling.

- Sheet metal protection at the bottom on both the sprue and ejector sides.

General advantages of RICO tools:

![]() Short Set-up Time - Change of cavity inserts cold and hot directly

Short Set-up Time - Change of cavity inserts cold and hot directly

in injection molding machine

![]() Short Maintenance - Open cold-deck - no moving parts

Short Maintenance - Open cold-deck - no moving parts

![]() Reduced maintenance costs - Durable-Cold nozzles

Reduced maintenance costs - Durable-Cold nozzles

(several million cycles)

![]() No expensive repairs - mold closing possible cold temperature

No expensive repairs - mold closing possible cold temperature

![]() Low production costs - RICO molds are working 24/7

Low production costs - RICO molds are working 24/7

![]() Up to 40% energy savings - compact build

Up to 40% energy savings - compact build

With the new Smartline and Topline tools, RICO is once again setting new standards in tool technology and offering its customers innovative, efficient and cost-saving solutions.

These product lines enable rapid adaptation to different production requirements and help to significantly increase the efficiency and cost-effectiveness of manufacturing processes.

If you’re interested,

contact us today.